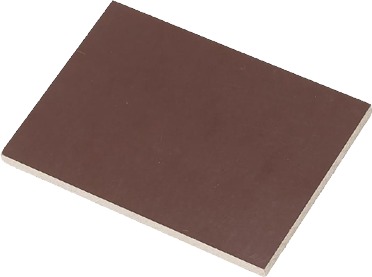

PHENOLIC LAMINATE (Bakelite/Canvas/Grade CE)

PHENOLIC LAMINATE – ELECTRICAL & MECHANICAL GRADE

Phenolic Laminates, also known as Bakelite Sheets, are high-pressure thermoset laminates made by impregnating layers of paper or fabric with phenolic resin and pressing them under heat and pressure. These laminates offer excellent electrical insulation, mechanical strength, and dimensional stability. They are available in both Electrical Grade and Mechanical Grade, designed to meet diverse industrial requirements.

Key Advantages

• High mechanical & electrical performance

• Excellent dimensional stability under load

• Resistance to oil, moisture, and temperature

• Easy to machine, drill, and fabricate

• Available in sheets, rods, and machined components

Available Forms

• Sheets: 0.5 mm to 100 mm thick

• Rods & Tubes: Custom diameters available

• Machined Components: Up to 2000 mm × 3000 mm (as per drawing)