Mica is a naturally occurring mineral renowned for its outstanding thermal resistance, electrical insulation capabilities, and dimensional stability under extreme heat. Hason Industries machines mica sheets into insulation washers, heater block shields, furnace panel liners, arc flash barriers, and coil supports for electrical and high-temperature pharmaceutical processing equipment. Because mica retains dielectric strength even at temperatures above 500°C, it is widely used in switchgear arc chambers, induction heater insulation, and heating coil separators.

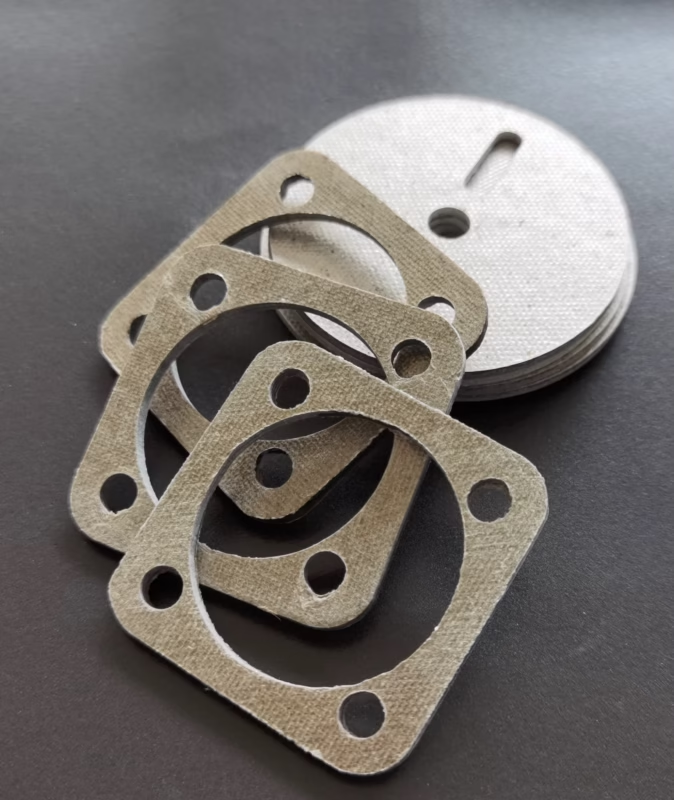

We stock mica sheets in thicknesses ranging from 0.5 mm to 50 mm and produce machined components up to 1,000 mm × 800 mm. Our CNC routing, precision sawing, and controlled drilling workflows allow us to create fine hole patterns, slotted vent surfaces, and custom thermal barrier geometries. Special dust extraction systems are used to maintain safety and edge quality.

In pharmaceutical equipment, mica is used in tablet dryer heaters, band heaters, and thermal insulation rings where direct metal contact could cause contamination or structural deformation. Its resistance to rapid temperature changes helps preserve shape during sterilisation cycles.

In electrical switchboards, mica prevents flashover, creepage currents, and surge conduction between conductive elements. Its ability to withstand arcing makes it an essential barrier in medium-voltage environments.

Hason Industries inspects each mica component for flatness, thickness uniformity, and chip-free edges. We provide reverse-engineered replacements for discontinued heater insulation plates and coil board profiles. Our CAD/CAM modelling ensures tight tolerances and consistent repeatability across batch production. Mica’s superior heat endurance and dielectric strength continue to make it indispensable in thermal and electrical isolation applications.