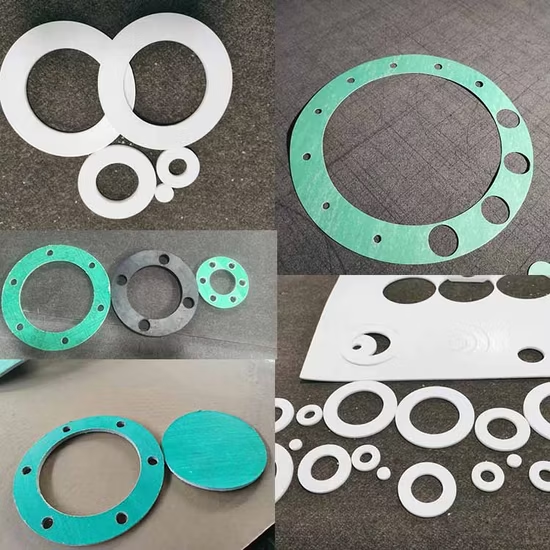

GASKETS

(Rubber/EPDM/PTFE/Non-Asbestos Cut Components)

Gaskets produced at Hason Industries are engineered sealing components designed to prevent leakage of gases, liquids, vapours, and chemicals under compression. Manufactured from materials such as PTFE, EPDM, rubber, and non-asbestos composites, our gaskets are widely used in pharmaceutical process piping, pump housings, sterile fluid transfer systems, electrical junction enclosures, and compressed air lines. Their dimensional stability ensures consistent sealing performance under fluctuating temperature and pressure conditions.

We machine and die-cut gaskets from sheet stock ranging between 0.5 mm and 10 mm thickness, producing profiles up to 1,200 mm in diameter or rectangular equivalents. Using CNC knife cutting, routing, die punching, and waterjet techniques, we deliver intricate geometries, bolt hole patterns, flange profiles, and groove designs suitable for OEM-grade equipment.

In pharmaceutical systems, chemically inert gaskets prevent contamination between process zones, making them critical in filling equipment, filtration assemblies, and CIP/SIP circuits. PTFE gaskets are preferred in corrosive chemical handling due to their resistance to acids and solvents. In electrical enclosures, gaskets prevent dust ingress and moisture intrusion, protecting sensitive components.

Hason Industries validates gasket compression set, edge uniformity, and thickness tolerance during quality checks. We manufacture both flat and formed gaskets, including spiral groove, tapered, and dovetail profiles. Reverse engineering allows us to replace worn OEM gaskets when technical drawings are unavailable.

Our CAD-based nesting optimisation reduces material waste while ensuring consistent repeatability in batch production. With ISO-quality frameworks, batch traceability, and fast turnaround, Hason Industries supports both maintenance departments and OEM manufacturers requiring reliable sealing solutions.