CERAMIC INSULATION

Ceramic insulation materials fabricated by Hason Industries are engineered for extreme heat exposure, thermal shock resistance, and electrical non-conductivity. Ceramic components are widely used in furnace linings, heater housings, welding fixtures, kiln insulation, ignition systems, and arc flash protection in switchgear assemblies. Their ability to withstand temperatures above 1,000°C makes them suitable for high-temperature pharmaceutical drying ovens, sterilisation heaters, and diffusion equipment. Ceramics are chemically inert, non-corrosive, and maintain structure even under rapid thermal cycling.

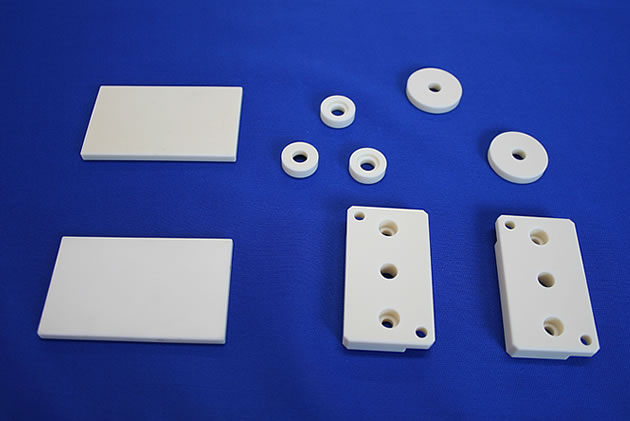

We fabricate ceramic plates, washers, spacers, arc shields, and custom blocks from sheet and billet formats ranging from 2 mm to 60 mm in thickness. Components up to 800 mm × 600 mm can be processed through precision grinding, diamond cutting, and specialised CNC routing systems designed for brittle materials. Our technicians employ controlled feed rates to prevent cracking and microfracture propagation.

In electrical manufacturing, ceramic components serve as coil supports, spark barriers, and terminal insulators in high-voltage applications. Their dielectric strength helps contain electrical discharge and prevent conductive leakage. Ceramic washers and standoffs are also used in PCB thermal isolation applications.

In pharmaceutical manufacturing, ceramic fixtures support thermal processing equipment, airborne sterilisation systems, and heating blade elements used for capsule sealing and material bonding. Their non-reactive nature ensures compatibility with disinfectants and cleaning agents used in GMP environments.

Hason Industries conducts flatness inspections, surface roughness tests, and hardness scanning on ceramic components to ensure stable installation and fitment. CAD-based geometry optimisation helps reinforce sections prone to heat-induced stress. With repeatable fabrication capacity and ISO-governed documentation, ceramic insulation remains essential for clients requiring both thermal control and electrical isolation.