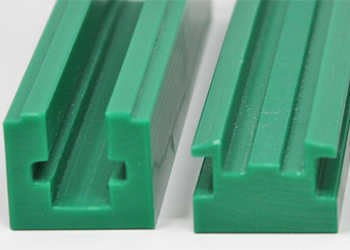

Ultra High Molecular Weight Polyethene (UHMWPE) is renowned for its extraordinary abrasion resistance, self-lubricating surface, and extremely low friction coefficient, making it a premium choice for components that face continuous sliding contact. At Hason Industries, UHMWPE is frequently machined into chain guides, conveyor wear strips, chute liners, star wheels, corner tracks, scrapers, and bumpers that are commonly integrated into pharmaceutical packaging lines, bottling plants, electrical equipment manufacturing, and food-grade processing machinery. UHMWPE does not absorb moisture and resists corrosive chemicals, making it ideal for wash-down environments and cleanroom-compatible assemblies.

We stock UHMWPE sheets and rods in thicknesses ranging from 8 mm to 200 mm and diameters up to 250 mm. With the aid of high-precision CNC routers, milling machines, and turning centres, we can produce UHMWPE components in sizes up to 2,500 mm in length and 1,500 mm in width. Our machining procedures prevent material warping and maintain tight tolerances, ensuring smooth operation in moving assemblies. UHMWPE’s impact-resistant nature helps to reduce machine wear, operational noise, and lubricant requirements.

In the electrical industry, UHMWPE is used as an insulating buffer material due to its dielectric properties and resistance to arc tracking. For pharmaceutical machinery, UHMWPE’s FDA-friendly variants offer excellent performance in contact surfaces, hoppers, conveyors, and product handling trays. Clients rely on our ability to custom-fabricate and assemble UHMWPE parts using advanced heat forming, chemical welding, and surface finishing techniques.

At Hason Industries, our ISO-driven processes ensure consistency in every production run. Each component undergoes dimensional inspection, edge finishing, and quality verification to meet OEM specifications. UHMWPE is a perfect metal replacement where friction reduction and wear resistance are priorities.