Polycarbonate is a transparent, impact-resistant engineering plastic known for its mechanical toughness, heat resistance, and optical clarity. At Hason Industries, Polycarbonate is used to produce machine covers, guard panels, inspection windows, viewing hoods, medical cleanroom enclosures, protective shields, safety doors, and protective housings in pharmaceutical and electrical manufacturing environments. Its shatter-proof nature makes it safer than glass around rotating machinery, reducing injury risk while allowing operators full visual access.

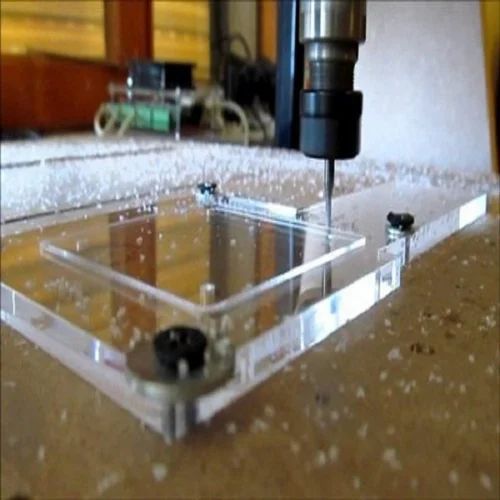

We stock Polycarbonate panels in thicknesses from 3 mm to 20 mm and can machine parts up to 2,400 mm × 1,500 mm. Using CNC routers, cold-bend tooling, heat-forming stations, and chamfering systems, we deliver curved guard panels, interlocking safety doors, and transparent barriers with high clarity. Polycarbonate can be drilled and slotted without cracking — a capability that our technicians execute carefully to preserve structural strength.

In pharmaceutical applications, Polycarbonate enclosures prevent airborne contamination while offering clear inspection visibility. In electrical industry setups, it functions as an arc-resistant protective guard and equipment shield. Polycarbonate also supports laser marking and engraving for safety instructions, batch coding, and operator guidance signage.

Hason Industries ensures that edges are polished, mounting slots are accurate, and cutouts align perfectly with machine frames. Our ISO-structured quality workflows verify transparency, dimensional tolerances, and stress-crack resistance. With short production cycles, replacement turnaround is fast, reducing downtime for OEM clients.