Polyether Ether Ketone (PEEK) is one of the most advanced high-performance engineering plastics available today, offering unparalleled high-temperature stability, mechanical strength, chemical inertness, and electrical insulation performance. At Hason Industries, PEEK is used to manufacture components that operate in extreme conditions, including semiconductor machinery parts, electrical insulation plates, compressor valve seats, bushings, bearing cages, pump impellers, wafer handling components, and high-load guide elements. PEEK’s ability to perform at temperatures up to 250°C continuously, combined with low gas permeability, makes it ideal for pharmaceutical sterilisation environments, autoclaves, and high-purity process lines.

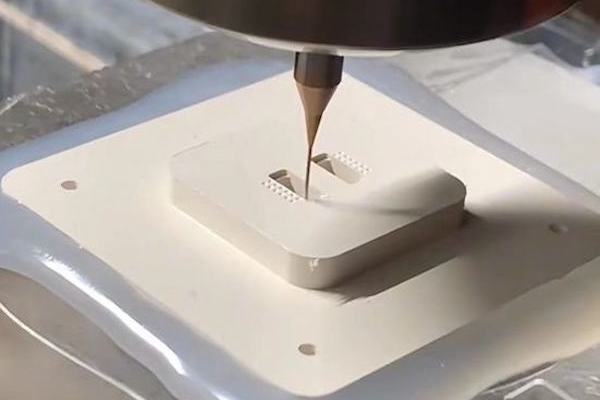

We maintain PEEK stock in sheet thicknesses from 6 mm to 80 mm and rods up to Ø120 mm. Our CNC milling and turning systems are capable of machining PEEK components up to 1,500 mm in length, holding very tight tolerances thanks to the material’s excellent dimensional stability. Due to its rigidity, PEEK requires carefully controlled cutting strategies and professional handling — a speciality that Hason Industries has mastered over years of experience.

In the electrical sector, PEEK is prized for its dielectric strength, flame resistance, and arc-tracking resistance, making it suitable for switchgear shields, insulator blocks, contact supports, and coil structures. For pharmaceutical equipment manufacturers, PEEK is the preferred material for product-contact surfaces that must not shed particles, degrade, or absorb moisture during humidification or sterilisation.

Hason Industries employs CAD/CAM systems to simulate tool paths and machining loads before production, reducing risk and improving surface finish. Our temperature-controlled machining environment helps maintain tolerance reliability. Every PEEK part undergoes post-production inspection using calibrated measuring instruments.

Because PEEK components often replace machined metal in harsh applications, clients trust Hason Industries to deliver critical parts with high reliability, repeatability, and certification documentation.