ACRYLIC (PMMA)

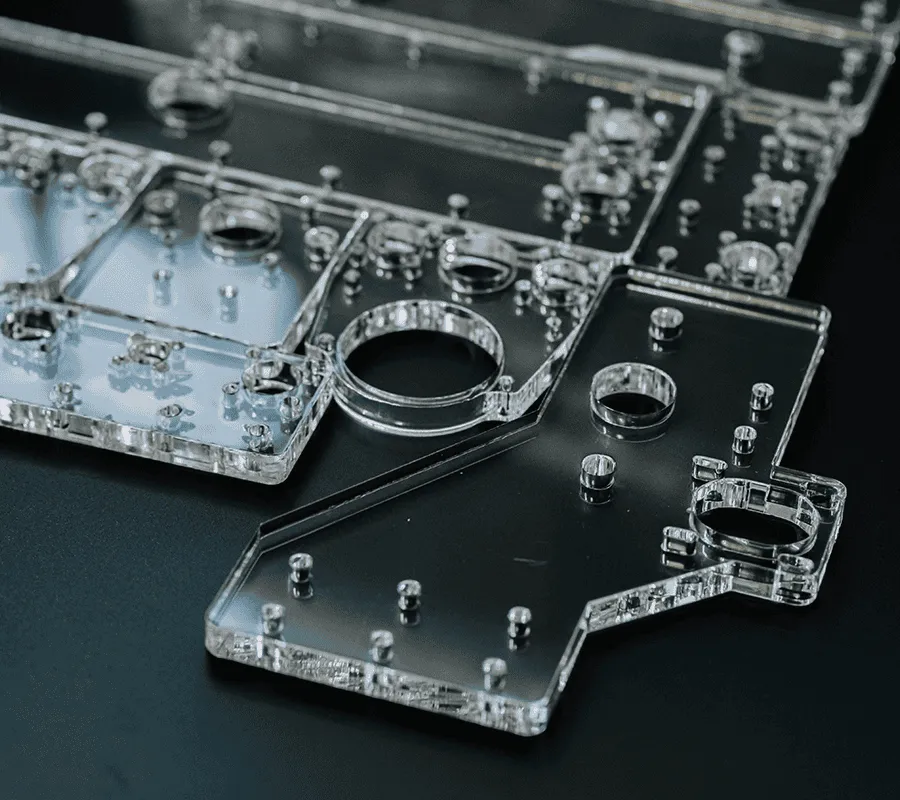

Acrylic, also known as PMMA, is a clear, lightweight, and aesthetically appealing engineering plastic widely used for display covers, inspection panels, control box windows, light diffusers, signage, instrument panels, pharmaceutical display shields, and enclosure doors. At Hason Industries, Acrylic is machined for applications requiring clarity, professional presentation, and structural rigidity without the fragility of glass. It is particularly useful in pharmaceutical inspection systems where visual monitoring is essential.

We stock Acrylic sheets in thicknesses ranging from 2 mm to 25 mm and can machine parts up to 2,300 mm × 1,400 mm. Our CNC routers and polishing equipment deliver clean edges and smooth, optically clear finishes. Acrylic can be laser-cut, engraved, heat-bent, and bonded to create 3D enclosures, display boxes, and safety domes. We also offer surface polishing to restore clarity after machining.

In electrical paneling, Acrylic is used as an inspection window for breakers, busbars, and control modules, allowing operators to monitor equipment safely. For pharmaceutical plants, Acrylic shields protect against cross-contamination without obstructing visual access. It is also used to fabricate podiums, operator control panels, safety instruction boards, and instrument housings.

Hason Industries prioritises finishing quality, avoiding micro-cracks and stress marks that could weaken Acrylic’s structure. Our CAD-driven milling strategies ensure clean corner radii and perfectly circular cutouts for switches and indicators. Every part undergoes optical clarity inspection, dimensional checks, and mounting alignment verification.

With our advanced machining equipment, sheet-bending stations, and bonding expertise, Acrylic components manufactured by Hason Industries consistently reflect precision, durability, and professional presentation — supporting the needs of both industrial machinery and corporate environments.